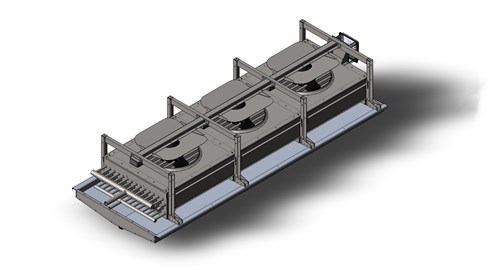

"Above Rail" style evaporator for use in food processing rooms where cleanability and workspace is critical. Designed for worker comfort and maximizing the use of workspace. Colmac Coil offers both a standard A+R and low profile configuration.

Hygienic design

- Hinged access panels on both sides standard for easy access

- Stainless steel materials of construction

- Full coverage insulated drain pan eliminates condensation and dripping

- Drainpan edge is angled inward, directing water into the pan

- Optional clean in place (CIP) piping available

- Anti-Microbial or Epoxy Coated fin material options

- Passivated welds to protect against contamination

- Washdown duty motors available

Easy installation and service

- Air deflector design provides good air coverage and is easy to remove for servicing the motor

- Hinged access panels on both sides standard for easy access to the coil core

- Designed for optimal recirculation rate to reduce system refrigerant charge

Maximize use of space and worker comfort

- Low installation height: 20-30” for low profile configuration and 30-50” for standard configuration

- Optimized fan speed for low sound pressure

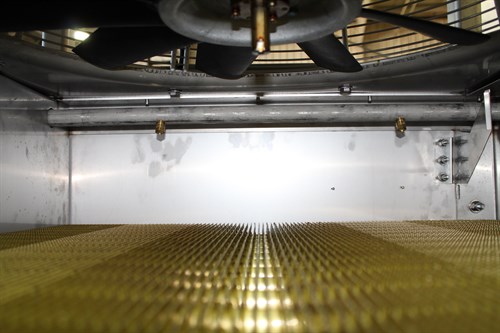

- Exposed fins on the lower edge of the entering row for increased airflow

A+R Standard

Designed to fit your footprint

- Capacity range: 3 – 25 TR

- 1-8 fan configurations

Tubes/fins options

- Aluminum tubes/aluminum fins

- Aluminum tubes/epoxy coated aluminum fins

- Steel tubes/galvanized steel fins

- 304 Stainless steel tubes/ 304 stainless steel fins

- 304 Stainless steel tubes/aluminum fins

- 304 Stainless steel tubes/epoxy coated aluminum fins

- 304 Stainless steel tubes/anti-microbial alloy fins

- 316 Stainless steel tubes/ 316 stainless steel fins

- 316 Stainless steel tubes/aluminum fins

- 316 Stainless steel tubes/epoxy coated aluminum fins

- 316 Stainless steel tubes/anti-microbial alloy fins

Coil casing

- G-235 galvanized steel

- 304 stainless steel

- 316 stainless steel

Fan type

- Composite

- Aluminum

- Stamped Aluminum

Hygienic full coverage drain pan design

- The A+R drain pan extends beyond the length and width of the air cooler, providing full coverage, preventing drips and splashing.

- The edge of the drain pan is angled inward, directing water into the pan.

- Drain pan is fully mounted before shipping.

Drain pan options

- Fully seal welded drain pan

- Galvanized steel

- Heat tracing

Defrost options

- Air

- Electrical

- Hot Gas

- Interlaced Glycol

- Water

Refrigerant feeds

- Recirculated top feed

- Recirculated bottom feed

- Flooded

- Direct expansion

Refrigerants

- Ammonia, C02, R22, R507A

- Calcium Chloride, Ethylene Glycol, Patassium Formate, Propylene Glycol, Water

Electrical options

All A+R air cooler fan motors come factory wired to a common terminal box.

- The A+R is by default equipped with individual terminal strip.

- VFD compatible

- 230 - 380 - 460 - 575/60/3 or 200 - 400/50/3 supply power

Fan motors

- Totally enclosed air over (TEAO) motor

- C-Face motors up to 1 Hp

- Wash down duty motors available

Hinged access panels on both sides

Air deflector design

Colmac Coil R&D Enginners developed and extensively tested the A+R air deflector that provides both a low installation height and directs air outward.

- Easily removed for servicing motor

- Directs air outward, providing good air coverage

Weld finish levels

Clean in place (CIP)

- Provides complete spray coverage of the entire coil core

- Automated and repeatable cleaning process

- In rooms above freezing, CIP provides a means of water defrost

Enhanced tube technology

Smart hot gas defrost

Smart hanger system

Aluminum-to-steel bimetallic couplers

A+R Low Profile

Colmac Coil developed a low profile A+R configuration for ultra low ceiling heights. To accommodate the lower installation height, there are a few differing features from the A+R standard design:

- 20 - 30 inch installation height

- Fan Rows: 2-6

- 1/4 horsepower motor

- Bolted 48 frame motor

- 230/60/1 or 460/1 phase

- Not inverter ready