What is the AIM Act?

The American Innovation and Manufacturing (AIM) Act, passed on December 27, 2020, mandates an 85 percent reduction in the production and consumption of hydrofluorocarbons (HFCs) by 2036, compared to historical baseline levels. This legislation grants the Environmental Protection Agency (EPA) the authority to address HFCs through a multifaceted approach, including the implementation of an allowance allocation program, support for transitioning to next-generation technologies across various sectors, and the issuance of regulations aimed at maximizing reclamation efforts and minimizing HFC releases from equipment.

AIM ACT HFC Phasedown Schedule

How does the AIM Act Impact Industrial Refrigeration Systems?

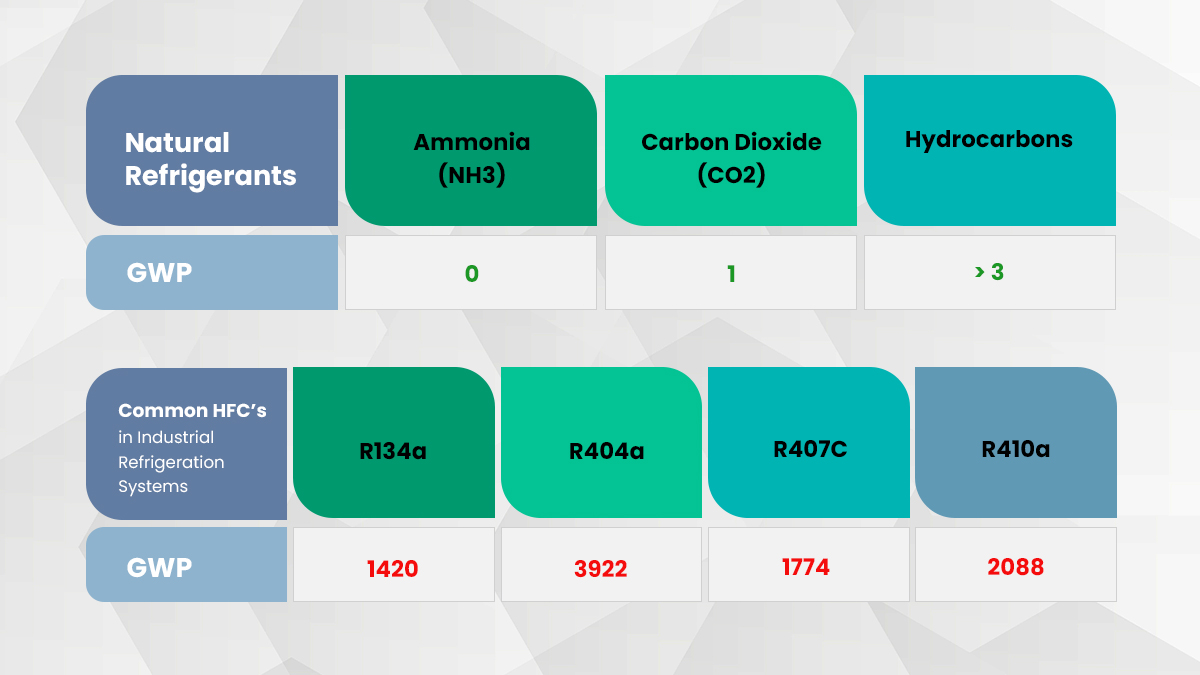

According to the new EPA proposals, commonly used HFC refrigerants with higher global warming potential (GWP), such as R134a, R404A, and R410A, will no longer be permitted in the majority of newly manufactured refrigeration, air conditioning, and heat pump systems and equipment. This marks a significant regulatory shift aimed at curbing emissions of potent greenhouse gases from the cooling sector.

The AIM Act is a federal mandate that requires all states in the United States to come into compliance with these regulations. States such as California and Washington have separate pieces of legislation that have additional GWP requirements for industrial refrigeration systems, in addition to Federal legislation.

|

Refrigeration, Air Conditioning, and Heat Pumps – Restricted Systems by Sector and Subsector

|

|---|

| Subsector | System | GWP | Installation Compliance Date |

|---|

| Industrial process refrigeration (not using chillers) |

With 200 or more lb refrigerant charge excluding high temperature side of cascade system and temperature of the refrigerant entering the evaporator above -30 °C (-22 °F) |

150 |

January 1, 2026 |

| Industrial process refrigeration (not using chillers) |

With less than 200 lb refrigerant charge and temperature of the refrigerant entering the evaporator above -30 °C (-22 °F) |

300 |

January 1, 2026 |

| Cold storage warehouses |

With less than 200 lb refrigerant charge |

300 |

January 1, 2026 |

| Cold storage warehouses |

With 200 or more lb refrigerant charge, excluding high temperature side of cascade system |

150 |

January 1, 2026 |

| Industrial process refrigeration (not using chillers) |

High temperature side of cascade systems and temperature of the refrigerant entering the evaporator above -30 °C (-22 °F) |

300 |

January 1, 2026 |

| Industrial process refrigeration (not using chillers) |

With less than 200 lb refrigerant charge and temperature of the refrigerant entering the evaporator above -30 °C (-22 °F) |

300 |

January 1, 2026 |

| Industrial process refrigeration (not using chillers) |

With 200 or more lb refrigerant charge excluding high temperature side of cascade system and temperature of the refrigerant entering the evaporator above -30 °C (-22 °F) |

150 |

January 1, 2026 |

For a full list of GWP requirements for subsectors, visit: Technology Transitions HFC Restrictions by Sector

Natural Refrigerants Provide a Long-Term Solution

Natural refrigerants such as ammonia (NH3), carbon dioxide (CO2), and hydrocarbons have inherently low or zero GWPs compared to synthetic refrigerants like HFCs. By transitioning to natural refrigerants, industries can significantly reduce their greenhouse gas emissions, aligning with the AIM Act's mandate to decrease HFC usage. Implementing natural refrigerants in industrial refrigeration systems is a cost-effective way to future-proof industrial refrigeration systems from future regulations on GWP.

A2L Refrigerants: An Additional Solution

A2L refrigerants, classified as mildly flammable, offer another viable solution for industries transitioning away from high-GWP HFCs. These refrigerants, such as R32, R1234yf, and R454B, have significantly lower GWPs compared to traditional HFCs, making them compliant with AIM Act regulations. A2L refrigerants strike a balance between environmental impact and performance, providing an alternative for systems where natural refrigerants may not be the most suitable option due to factors like cost, retrofit complexity, or safety concerns.

Incorporating A2L refrigerants into industrial refrigeration systems can help businesses meet the AIM Act's phasedown requirements while maintaining efficiency and reliability. However, due to their mild flammability, these refrigerants require careful consideration of safety measures during system design and installation.

Partner with Colmac Coil

Colmac Coil Manufacturing has decades of experience in designing and manufacturing industrial refrigeration air coolers, heat pumps, condensers and fluid coolers for refrigeration systems using natural refrigerants. This includes design codes that certify performance and pressure rating, EC fan motors that improve efficiency, and a 5-year warranty. We look forward to finding a solution with you.