HygenAir™ Selection Software

Designed in proprietary Colmac Coil HygenAir™ Selection Software, the HygenAir™ A+H Hygienic Air Handler is available in several unit sizes and configurations for all refrigeration system types. The HygenAir™ Software provides a full hygienic air unit specification and a quote in a matter of minutes, including, exact unit specification drawings, design data sheet, price summary report, and pricing details.

Exhaust Air Fans:

- Electronically commutated (EC) fans up to 40,000 cfm units

- Tube-axial fans are available for larger cfm sized units

Supply Air Fans:

- Plenum fans with direct drive motors

- Non-overloading, single thickness, airfoil type impeller

- Standard TEFC, premium efficiency motors

Controls

- Allen Bradley Compact Logix PLC System with ethernet communication

- Panel View Plus 7 with a 6-inch display mounted on the face of main control panel.

- Direct Fire Burner Controls: Includes burner startup, shutdown, and safety monitoring.

- VFD controls for both supply and exhaust fans

- Fused disconnects

Filters:

The filtration system is a critical component of the hygienic air handing system, that removes airborne contaminants from outdoor air or various processes within the processing space. Excellent performance in difficult operating conditions, lightweight and easy to install, and fully resistant to corrosive environments. An optional extra set of filters can be included.

- Pre-Filters: Available in minimum efficiency reporting value (MERV) 8 or 9

- Intermediate-Filters: Available in MERV 9, 11, and 13

- Final-Filters: Available in MERV 11, 13, 14, 15, 16 and HEPA H13

Cooling and Reheat Coils:

As a premier manufacturer of evaporator coils for industrial refrigeration markets, Colmac Coil has the flexibility to offer a wide range of options for selecting the best evaporator for the Hygienic Air Handler. This includes various tube diameters and fin thicknesses, inline or staggered tube patterns, a full range of tube and fin materials, and coils designed and manufactured per the requirements of ASME B31.5.

- Standard stainless-steel tube/aluminum fin coil construction

- Other fin/tube materials are available to meet the requirements of every application

- Optional anti-microbial (CuNi) fins

- Optional epoxy coated aluminum fins

- Coils are designed and manufactured by Colmac Coil, as per the requirements of ASME B31.5

Drain Pan:

- Full coverage 304 stainless steel drain pans for the entire unit interior

- All drain pan fasteners are 304 stainless steel

- Dual pitch design allows complete liquid drainage from interior of the unit

- Fully welded drain pans with hygienic weld finish options

Base:

- Fully welded steel frame with primer and industrial grade paint finish

- Fully insulated base with polyurethane spray foam for thermal/vapor barrier

- Permanent lifting lugs for crane rigging

Wall Panels:

- Standard G235 galvanized steel interior and exterior walls

- Optional 304 stainless steel interior

- Standard 2-inch-thick fiberglass insulation enclosed in wall panels

- All wall joints are sealed with food grade sealant

Return Air and Fresh Air Dampers:

- Low leakage air-foil control damper

- All aluminum construction with stainless steel trim

- Standard modulating NEMA 4 actuators with position feedback

Heating Options:

- Direct fired propane or natural gas burner designed for 80° F temperature rise

- Optional steam or hot water heating coils are available

Unit Access

Access doors are included for ease of access to all compartments.

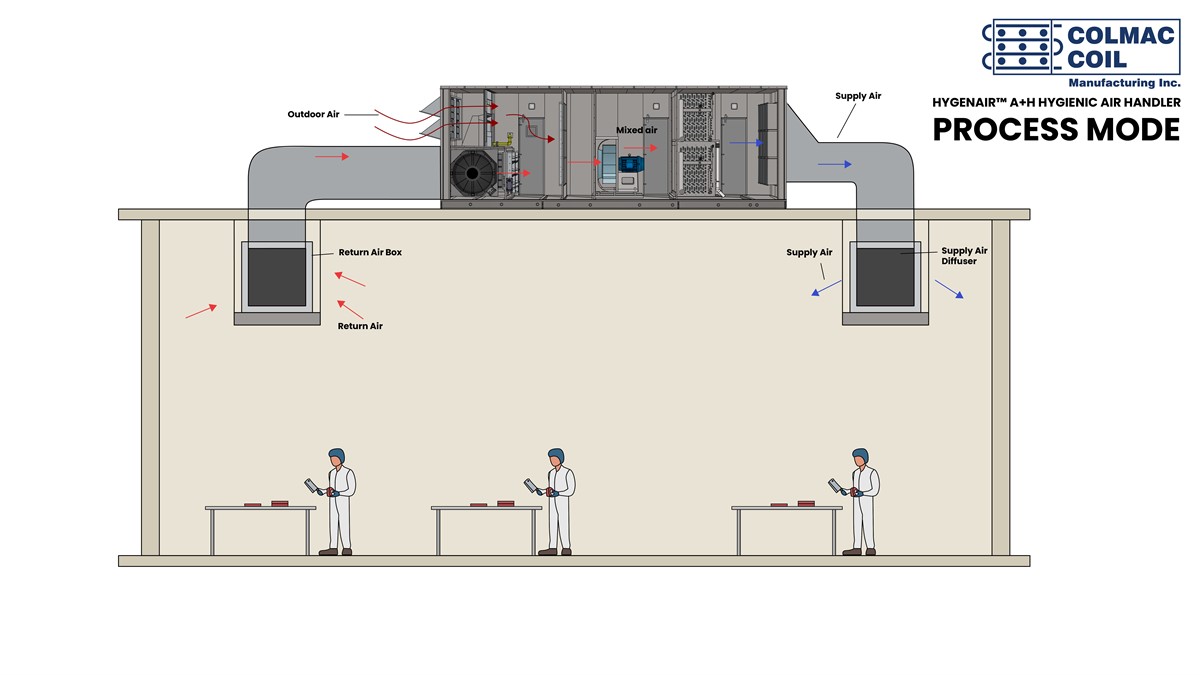

Process Mode:

In the production mode, Colmac Coil's Hygienic Air Handler blends fresh outside air with indoor air to maintain positive air pressure, compensating for air escaping through openings. The mixed air is filtered, circulated by efficient plenum fans, and delivered through diffusers or ducts. The system includes exhaust fans for precise pressure control. It's controlled by an Allen Bradley PLC system.

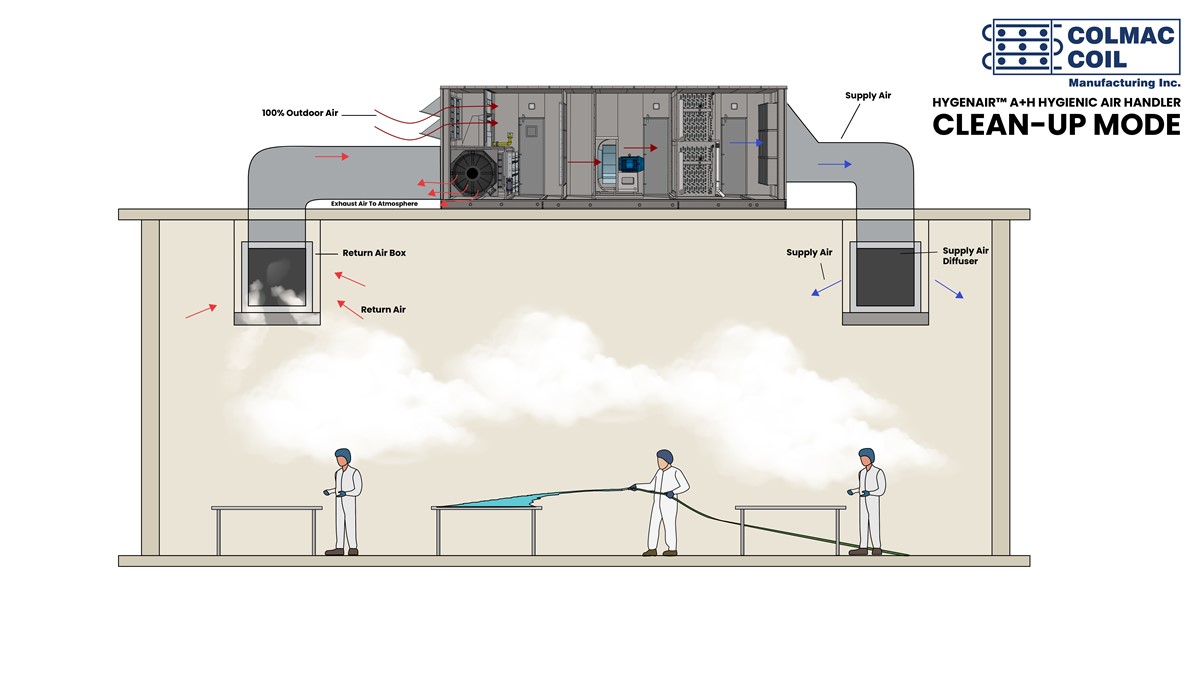

Clean-Up Mode:

During clean-up mode, the system draws in 100% fresh air from outside, conditions it to remove moisture, and expels it using exhaust fans. Cooling or heating may be used based on outside conditions for effective moisture removal.

Start Up Support:

A Colmac Coil technician is available to program the controls at the job-site, ensuring the hygienic unit is optimized for each facility.